I was eagerly awaiting this shipment. Every day was worth the wait for such an intricate and high-quality product. Thank you and best regards, Bartosz.

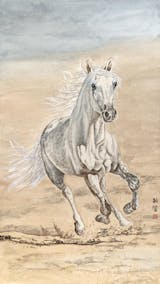

Larger size paper can present more creative idea, the paper is good for drawing animal

This is the second handmade brush I have had the pleasure of ordering from Ms Chiyomi Tanaka through Keitaro from Ichi inc., Japan.

Ms Chiyomi is one of the last few master brush makers in Nara, the spiritual home of the Japanese art of Shodo. I recommend watching the YouTube video interview of Ms Chiyomi and her brush-making process.

I find that with using a brush like this, the artwork carries the spirit of both me and the artist who made the brush, making it doubly special. I am very much looking forward to buying from Ichi inc. again!

A lovely larger-sized pure wool calligraphy brush which allows a far greater range of expression than more rigid beginner’s brushes. I am glad to have a piece of excellent craftsmanship from one of Nara’s last master brush-making artisans. Thanks for the fast dispatch!

ありがとうございます!

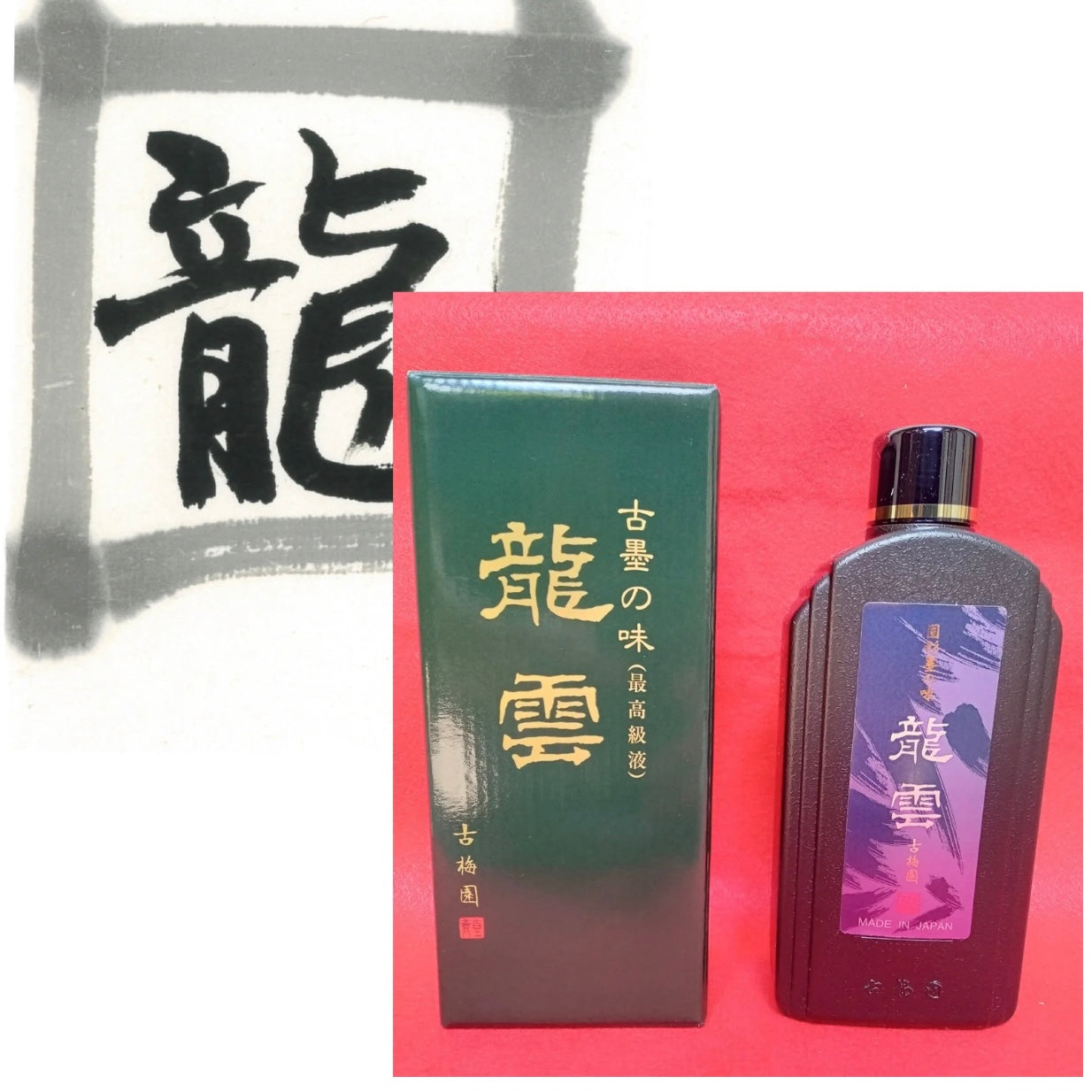

The ink stick is good with wide range of black colour and is good for art work in black and white tone